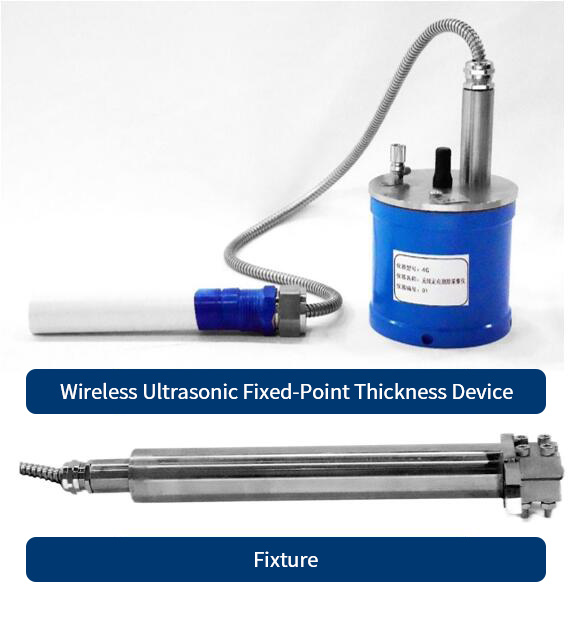

Wireless Ultrasonic Fixed-Point Thickness Device products are used to replace expensive online thickness device systems, solve the problem of weak data reliability and difficult manual thickness device implementation, and provide a new detection or monitoring approach for equipment integrity management.

Wireless Ultrasonic Fixed-Point Thickness Device products are used to replace expensive online thickness device systems, solve the problem of weak data reliability and difficult manual thickness device implementation, and provide a new detection or monitoring approach for equipment integrity management.

|

Line No |

Parameter |

Technical Overview |

|

1 |

Number of ultrasound channels (measuring points) |

Single channel, customizable multi-channel integrated |

|

2 |

Ultrasound mode |

Pulse reflection and penetration |

|

3 |

frequency range |

500KHz-10MHz |

|

4 |

Sampling accuracy |

14 digits |

|

5 |

Thickness measurement accuracy |

0.02mm |

|

6 |

sampling rate |

100M/second |

|

7 |

Battery life |

≥3 years/day/1 time |

|

8 |

Instrument operating temperature |

-40 ℃~+65 ℃ |

|

9 |

Operating temperature of ultrasonic probe |

Room temperature~+100 ℃/100 ℃~+600 ℃ |

|

10 |

Communication methods |

Wireless LORA, 4G/5G, online RS-485 communication protocol |

|

11 |

Power supply |

Lithium batteries can also be customized with wired 24VDC power input |

|

12 |

Installation method |

The thickness gauge can be installed with integrated bolts/fixtures, or the thickness collector and probe can be installed separately. A 1-2 inch pipe pile bracket (2-inch galvanized pipe is sufficient) is required |

|

13 |

Maximum collection rate |

Once per minute |

|

14 |

Minimum collection rate |

Once/24 hours |

|

15 |

Hazardous Area Certification |

Ex d IICT4 Gb |

CMAS Corrosion Rate Monitor

High-Precision Resistance Acquisition Analyzer