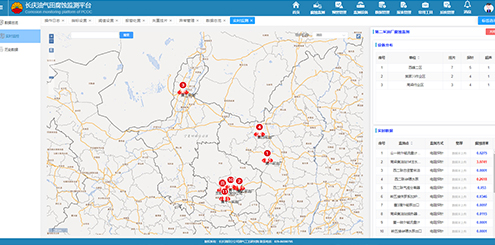

To grasp the corrosion situation of various pipelines, eliminate safety and environmental hazards, establish a unified corrosion monitoring platform, achieve automatic collection of corrosion monitoring data, prediction and evaluation of corrosion of well station equipment and pipelines, display of corrosion protection effects, and provide data support for surface system anti-corrosion design and pipeline governance. On the basis of following the standards and specifications of the integrated platform for oilfield geological engineering, as well as the petroleum exploration and production data model (EPDM 2.0) and oilfield exploration and development data model (CQEDM1.0) of China National Petroleum Corporation, a corrosion monitoring platform for oil and gas fields is developed using technologies such as microservices+container architecture and cloud native development. Realize the unified management of corrosion monitoring data and monitoring equipment for the three-level management units of oilfield companies, factories (offices), and operation areas (central stations), connect the data links of the group company and oilfield company's related business unified and self built systems, achieve data interconnection, and conduct comprehensive analysis of corrosion data, realizing the use of historical data and prediction models for corrosion warning. The platform adopts a microservices architecture design, based on the design concept of service interfaces, to achieve front-end and back-end separation and standardize module coupling. Fully consider the processing of large and real-time data, as well as the expansion and improvement of future system applications, and design the system architecture. Connect the A5 system, GIS system, and oil and gas plant database links to achieve automatic data extraction.

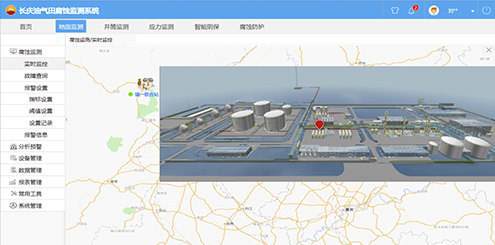

3D visualization

Common tools

Report management

Data management

Equipment management

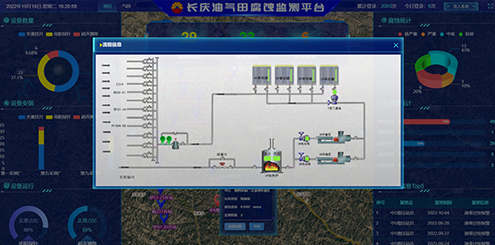

Analyze early warning

Corrosion monitoring